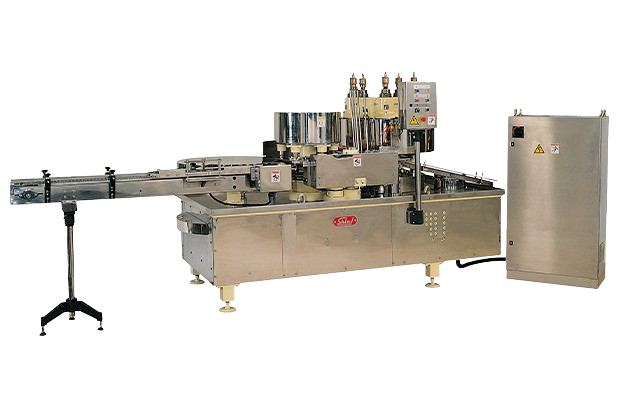

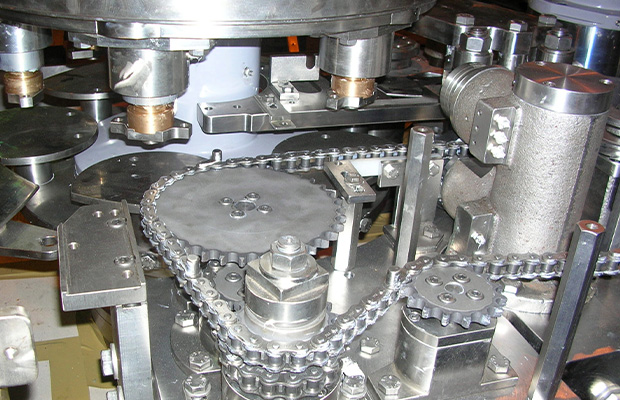

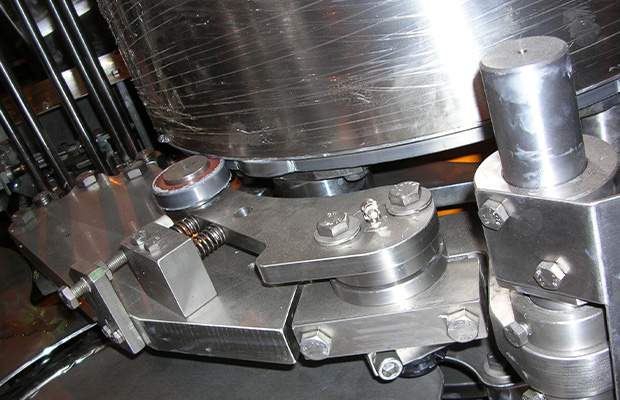

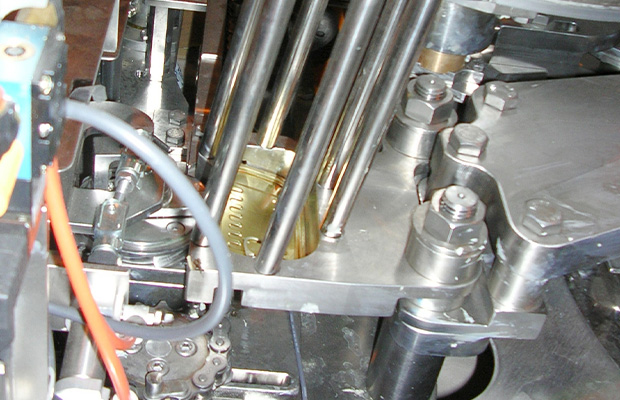

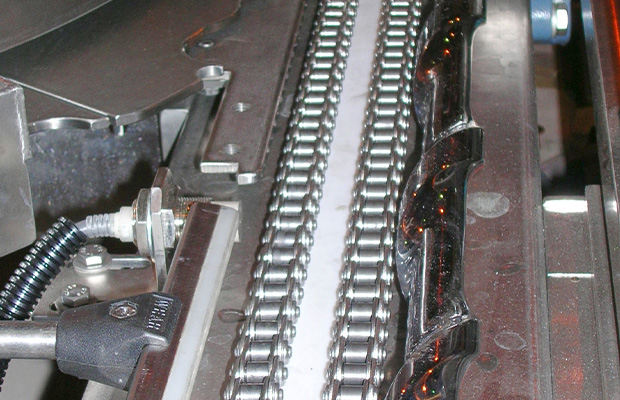

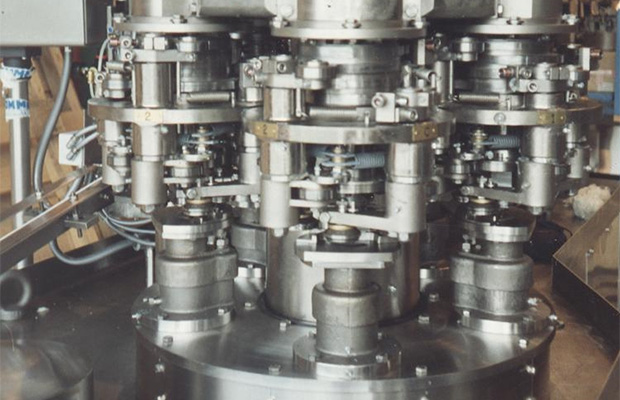

S-V465 Automatic Irregular Can Seamer with Clincher is specially designed for irregular can closing. Filled can is fed forward through a timing screw and a turret to meet with end. Clinching chuck and two clinching rollers push food down and clip end and can body together. Then, clinched can is carried by a turret and chain to enter seaming station. Lifter plate lift can up. Four seaming rollers undertake seaming operation. Seamed can is carried out and ejected by a turret. Equipped with five sets of seaming head. A concise seaming head with adjustable chuck set, make seaming quality meet international standard. Each seaming arm is controlled by an individual seaming cam and a copy disc is to guide rollers turn accordingly. Simple structure and multiple safety devices, easy for operation and maintenance.