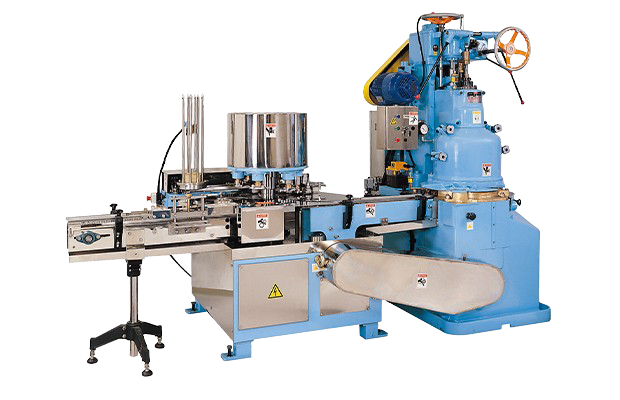

Standardized Food Can Production Line

Designed for speed, versatility, and uncompromising quality in automated food canning.

Challenges Commonly Faced in the Food Can Industry

Canned food diversity and safety standards call for expert packaging solutions.

With changing consumer diets and growing demands for high-volume, efficient production, Traditional production lines often face the following issues

High Production Demands

Continuous high-speed operation increases the risk of equipment failure

Varied Product Requirements

Frequent changes in can types and sizes make line switching difficult

Inconsistent Quality Control

Unstable sealing quality affects product shelf life

High Operational Costs

Heavy reliance on manual labor and long downtimes for line changes

Strict Hygiene and Safety Standards

Equipment must comply with food safety regulations

The industry needs smarter, more flexible solutions. Shin I Machinery

delivers exactly that—with proven reliability and deep expertise.

Global Packaging Partner You Can Trust

With over 60 years of experience since 1956, Shin I Machinery has

established itself as a leading name in can-making and canning machinery. Our

solutions are trusted by food and beverage producers in over 80 countries.

We understand the critical needs of food can production: efficiency, diversity

and hygiene. With this foundation, we deliver fully integrated, tailored

turnkey systems to help you overcome production bottlenecks and stay ahead in a

competitive market.

What We Offer to the Food

Can Industry

- Fully integrated systems from can shaping, filling, and seaming to washing, inspection, and packaging

- Optional automation for material handling, warehousing, and logistics integration

- Supports popular can sizes: Round can / Oval can / Luncheon meat can / Customized

- SUS stainless steel, corrosion-resistant and easy to clean

- Enhanced food safety and longer preservation

- Optional CIP system, compliant with HACCP / GMP standards

- Pre-sale consultation, capacity planning, and layout design

- On-site installation, training, after-sales maintenance, and original spare parts supply

Compatible with a Wide Range of Food Can

Fish can

Vacuum seaming, Maintaining food freshness and flavor

Fruit can

Anti-oxidation, extended shelf life, mass production

Milk powder can

Multiple can formats, accurate seaming, stable packaging

Your Strategic Partner for Food Market Success

In the highly competitive food market, how can you quickly launch new products while maintaining high quality and lowering costs? Shin I Machinery is dedicated to being your trusted strategic partner, helping you secure a strong foothold in the market and face future challenges.