Smarter Beverage Can Making Solutions

Engineered for High-Speed, Multi-Format Production with Uncompromising Quality

Challenges Commonly Faced in the Beverage Industry

A Rapidly Changing Market Demands Smarter Packaging Lines

The modern beverage industry is under constant pressure to bring products to market quickly, produce a wide variety of items in small batches, and maintain high efficiency. Traditional production lines often face the following issues

High Production Demands

Continuous high-speed operation increases the risk of equipment failure

Varied Product Requirements

Frequent changes in can types and sizes make line switching difficult

Inconsistent Quality Control

Unstable sealing quality affects product shelf life

High Operational Costs

Heavy reliance on manual labor and long downtimes for line changes

Strict Hygiene and Safety Standards

Strict Hygiene and Safety Standards

The industry needs smarter, more flexible solutions. Shin I Machinery delivers exactly that—with proven reliability and deep expertise.

Global Packaging Partner You Can Trust

With over 60 years of experience since 1956, Shin I Machinery has established itself as a leading name in can-making and packaging machinery. Our solutions are trusted by food and beverage producers in over 80 countries.

We understand the critical needs of beverage production: efficiency, flexibility, consistency, and hygiene. With this foundation, we deliver fully integrated, tailored turnkey systems to help you overcome production bottlenecks and stay ahead in a competitive market.

What We Offer to the Beverage Industry

- Optional automation for material handling, warehousing, and logistics integration

- Fully integrated systems from can shaping, filling, and seaming to washing, inspection, and packaging

- Optional automation for material handling, warehousing, and logistics integration

- Fully integrated systems from can shaping, filling, and seaming to washing, inspection, and packaging

S-C7-24 + S-B45

- Supports popular can sizes: 250ml / 330ml / 500ml / Custom

- Modular design allows fast format switching and minimal downtime

- SUS stainless steel, corrosion-resistant and easy to clean

- Optional CIP system, compliant with HACCP / GMP standards

- Pre-sale consultation, capacity planning, and layout design

- On-site installation, training, after-sales maintenance, and original spare parts supply

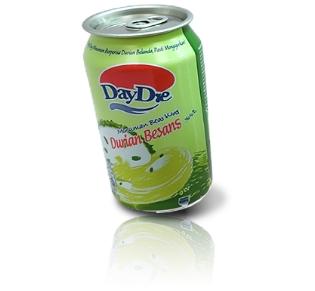

Compatible with a Wide Range of Beverages

Carbonated Drinks

High-pressure filling, airtight sealing, anti-burst can design

Juices / Tea

Anti-oxidation, extended shelf life, accurate sealing

Functional Drinks

Multiple can formats, fast changeovers, small batch runs

OEM Co-Packers

Highly flexible layouts, modular switching for varied SKUs

Your Strategic Partner for Beverage Market Success

In an industry where speed, cost control, and product quality define success, Shin I Machinery helps you stay competitive and agile. Whether you’re launching a new brand or scaling up your operations, we’re here to support your growth.