S-B10A Automatic Lining-Drying Machine

S-B10A Automatic Lining-Drying Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-B10A Automatic Lining- Drying Machine is specially designed for small round end. Curled end is separated by a pair of separating knives at end magazine ;then feeding bars send it to lining station. End is lifted up by a turning chuck. A mechanical gun (or electronic gun) undertake the lining task to evenly spray compound along the end fringe. Lined ends are transferred by a turret to enter drying oven. Inside the drying oven , heating air is created and recycled by an electric heater and a blower. Ends are carried up through eight transfer screws and are ejected out through a magnetic (or suction type) belt. With recycleable lubricating system and multiple safety devices, easy for maintenance and can size changeover.

Specifications

| Machine Type | S-B10A | |

|---|---|---|

| Range of Can Dia. | 200 - 404D | |

| Capacity Per Min. | 200 - 307D Up to 300 pcs/min. | |

| 401 - 404D Up to 250 pcs/min. | ||

| Horse Power Required and Heater | Main Motor | 3HP x 1 |

| End Discharge Motor | 1/4HP x 1 | |

| Blower | 1/2HP x 1 | |

| Heater | 15KW | |

| Compressed Air Required | 2kg/cm2 x 10L/Min. | |

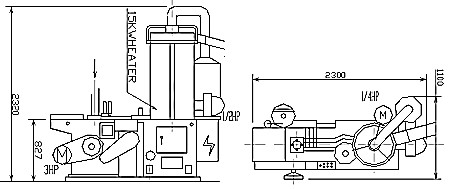

| Floor Space Overall Height | 2300 x 1100 x 2320 mm | |

| Net Weight | 2200 kgs | |

Features

- With single nozzle for compound spray, easy to adjust the film volumn.

- Drying Oven is vertical design, hence save space.

- Safety devices provided to ensure M/C running safely.

- Auto temperature controller enable to adjust the best curing temperature.

- Easy adjustment and quick for can size change over.

- Mechanical lining gun equipped , Electric lining gun is available on request.

- Drying oven equipped with electric (resistance) heating system.

- Ends are lifted by eight screw posts in drying oven and carry out by a magnet conveyor.

- System for variable lower chuck speed control by an inverter is available on request.

- With special end swing stopper on magazine, stacked ends never touch slide bar to avoid scratch.

- Recommended for Water base compound.

Layout Dimension