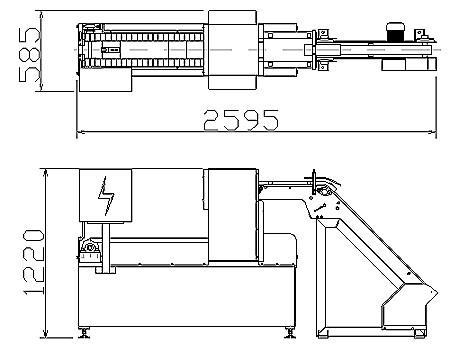

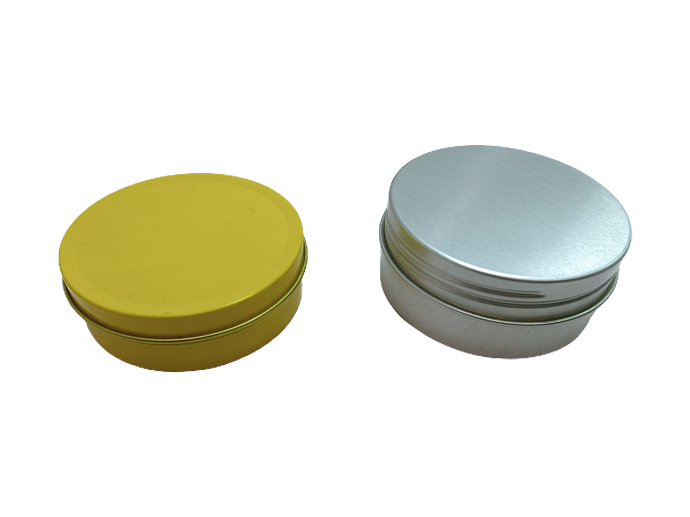

S-B10AL2 Automatic End Counter and Stacker is specially designed for big round end and is recommended to link with one set of lining/drying machine S-B10AL. Dried ends are guided by a chute to reach the inlet magnetic conveyor then enter collection channel. A pair of separating plate and a sensor undertake counting and collecting task. Counted ends stay at a support plate then are lowered down to the surface of two flat belts by an air cylinder. Ends are slowly moved out by the belt. Finally, ends are removed and put into carton box manually. Simple design and multiple safety devices, easy for maintenance and can size changeover.