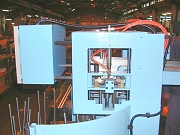

S-B10AL3 Automatic End Counter and Stacker Machine

S-B10AL3 Automatic End Counter and Stacker Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-B10AL3 Automatic End Counter and Stacker is specially designed for round central lid (for paint can or biscuit can) and is recommended to link with one set of central lid curling machine S-B14C. Curled lids are guided by a chute to reach the inlet magnetic conveyor then enter collection channel. A pair of separating plate and a sensor undertake counting and collecting task. Counted lids stay at a support plate then are lowered down to the collecting station of a index turning table. The table turn to move the piled lids out. Finally, ends are removed and put into carton box by hands. Simple design and multiple safety devices, easy for maintenance and can size changeover.

Specifications

| Machine Type | S-B10AL3 |

|---|---|

| Range of Cnd Dia. | 307 - 714 D |

| Capacity Per Min. | Up to 120 CPM |

| Horse Power Required | 1/4HP x 2 |

| Compressed Air Required | 3kg/cm2 x 10L/Min. |

| Floor Space Overall Height | 2430 x 970 x 1540 mm |

| Net Weight | 1000 kgs |

Features

- Easy for end size changeover and build for long life using.

- Precise ends counting, quick for resetting and adjusting.

- Multi-safety design for machine and personnel safety.

- Suitable for central lids counting and stacking.

- With PLC control system for ends auto stacking and counting operation.

- Equipped with inverter for variable speed control.

Layout Dimension