S-B10RP Automatic F.O.E. Repair-Drying Machine

S-B10RP Automatic F.O.E. Repair-Drying Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-B10RP Automatic F.O.E Repair- Drying Machine is specially designed for small tin round full open end. Curled end is separated by a pair of separating knives at end magazine ; then feeding bars send it to spraying station. End is lifted up by a turning chuck. A NORDSON spraying gun undertake the spraying task to evenly spray lacquer along the end scoring line to avoid rust. Whole surface spray or opposite end side spray can be done. Sprayed ends are transferred by a turret to enter drying oven. Inside the drying oven , heating air is created and recycled by an electric heater and a blower. Ends are carried up through eight transfer screws and are ejected out through a magnetic belt and cooled down by air blowing. With recycleable lubricating system and multiple safety devices, easy for maintenance and can size changeover.

Specifications

| Machine Type | S-B10RP | |

|---|---|---|

| Range of Can Dia. | 200 - 404D | |

| Capacity Per Min. | 200 - 301D Up to 250 pcs/min. 307 - 401D Up to 250 pcs/min. |

|

| Horse Power Required and Heater | Main Motor | 3HP x 1 |

| End Discharge Motor | 1/4HP x 1 | |

| Blower | 1/2HP x 2 , 2HP x 1 | |

| Heater | 15KW | |

| Compressed Air Required | 5kg/cm2x 50L/Min. | |

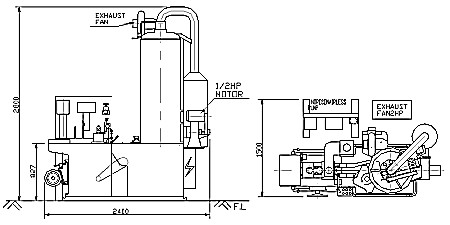

| Floor Space Overall Height | 2400 x 1500 x 2800 mm | |

| Net Weight | 2400 kgs | |

Features

- With NORDSON airless spray system for lacquar coating, easy to adjust the film volumn.

- Drying Oven is vertical design, hence save space.

- Safety devices provided to ensure M/C running safely.

- Auto temperature controller enable to adjust the best curing temperature.

- For Food full open end scoring line lacquer reparing to avoid rust.

- Drying oven equipped with electric (resistance) heating system.

- Can be used to repair inner side or outer side of full open end.

- Ends are lifted by eight screw posts in drying oven and carryout by a magnet conveyor.

- With special end swing stopper on magazine, stacked ends never touch slide bar to avoid scratch. System for variable lower chuck speed control by an inverter is equipped.

- Smoke discharge system to outdoor is to be built by buyer.

Layout Dimension