S-B10TC Automatic Twist-Off Cap Lining Machine

S-B10TC Automatic Twist-Off Cap Lining Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-B10TC Automatic Twist-Off Cap Lining Machine is designed for the sealing compound spraying on twist-off cap. Formed cap is carried into by a conveyor , then is sent to an index turret to lining station. A set of electronic lining gun undertake compound spraying task. Then, lined cap is turned by a disc to evenly spray compound on the cap by centrifugal force. Compound can be distributed along cap fringe circumference or cap whole round surface. Simple structure and multiple safety devices, easy for operation and maintenance.

coming soon

coming soon

Specifications

| Machine Type | S-B10TC |

|---|---|

| Range of Can Dia. | Φ30 - 80mm |

| Capacity Per Min. | Up to 150 cpm |

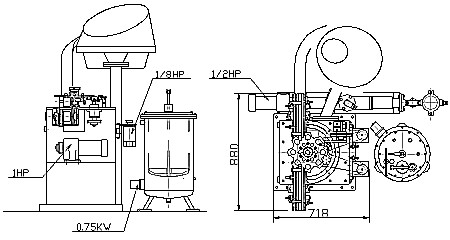

| Horse Power Required | 1HP x 2, 1/9HP x 2, 0.75KW |

| Floor Space Overall Height | 1456L x 1436W x 1557H mm |

| Net Weight | 950 kgs |

Features

- Mounting with electronic gun and control unit for cap compound lining.

- Easy for compound weight adjusting.

- Use variable speed controller, easy for your output production control.

- Safety devices provided to ensure machine running safely.

- Cap guide and Turrets with hard chromium plating to prevent scratch.

- Easy adjustment and quickly for cap size change-over.

- Mounting with Electric gun caps feeding unit for auto cap feeding.

- Can be directly connected with twist-off cap knurl forming machine.

- Easy changeover between ring lining and whole inner area spray.

Layout Dimension