S-B17V Automatic Vertical Beading Machine

S-B17V Automatic Vertical Beading Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

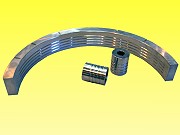

- Close View / Tooling

- Specification / Features

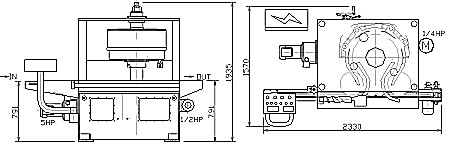

S-B17V Automatic Vertical Beading Machine with vertical design is easily linked and work together with automatic double seamer. Flanged can body is carried by a timing screw and a turret to let beading roller enter can inside. Bead clusters are created due to pressing between beading roller and a fixed arc beading rail. With recycleable centralized lubricating system and multiple safety devices, easy for maintenance and can size changeover.

coming soon

Specifications

| Machine Type | S-B17V |

|---|---|

| Range of Can Dia. | 202 - 401D |

| Range of Can Height | 90 - 210 mmH |

| Capacity Per Min. | Up to 1200 Cans |

| Horse Power Required | 5HP |

| Floor Space Overall Height | 2530L x 1130H x 2120W mm |

| Net Weight | 4500 -6200 kgs |

Features

- Vertical design easy to connect with auto double seamer.

- Recycleable central control lubricating system.

- Use human-machine interface (touchable monitor) control system and inverter for setup and variable speed control.

- Use inverter for variable speed control.

- Full automatic control system for canmaking line requirement.

- Multi-safety design for machine and personnel safety.

- Beads on can body are formed due to pressing between turning beading roller and a fixed arc beading rail.

Layout Dimension