S-B18C(CL,CLL) Automatic Double Wheel Curling Machine

S-B18C(CL,CLL) Automatic Double Wheel Curling Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

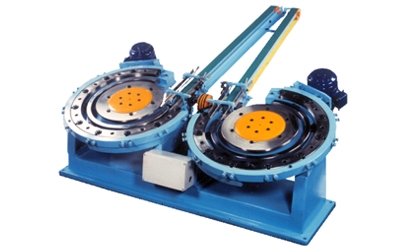

S-B18C(CL,CLL) Automatic Double Curling Machine with double curling wheel is designed to inward curl the end fringe on round end. Ends punched by a press are delivered by chutes or conveyors into the curling machine. Two turning curling wheels and two set of fixed curling segment curl the end fringe gradually. Two central support rings are to support the ends while they are being curled so as to avoid deformation. Simple structure, easy for operation and maintenance.

coming soon

Specifications

| Machine Type | S-B18C | S-B18CL | S-B18CLL |

|---|---|---|---|

| Range of Can Dia. | 200 - 401D | 401 - 603D | 603 - 800D |

| Curling Wheel | Double | ||

| Capacity Per Min. | Up to 600 Ends | Up to 300 Ends | Up to 240 Ends |

Features

- Tooling is made from special alloy steel and harden treatment.

- End guide with stainless steel or polish treatment.

- Easy adjustment and quickly for changeover.

- Can connect with conveyor to linning and drying M/C to reduce labor cost.

- Perfect products and buit for long life satisfy the requirement of can making.

- Can be used for aerosol cone/dome curling.

- Nine piece outer segments is equipped for each wheel.

- Safety micro switch at the entrance to detect end jam.

- With motorized inlet conveyor.

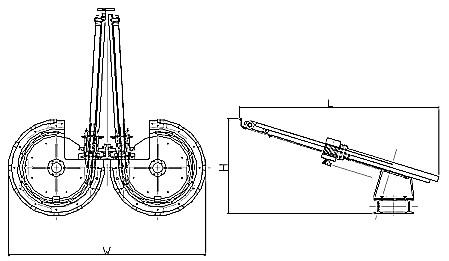

Layout Dimension