S-B18GL Automatic Can Body Drawing Machine

S-B18GL Automatic Can Body Drawing Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

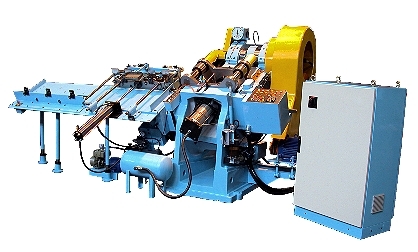

S-B18GL Automatic Can Body Drawing Machine is built for two-piece can drawing Piled strips are lifted by a pair of hydraulic cylinders then suck pads send strips one by one to the strip feeding station. (also can link with Automatic Strip Feeder S-B18-2). Reciprocating feeding bar at feeding station pushes the strip into punch tooling. Formed can body or end is ejected out via. air blowing to the rear while strip scrap is ejected out by a pressing roller to the side. Equipped with twin sets of punch tooling. Punch tooling is made of alloy steel or tungsten carbide; besides, an air cushion system is incorporated. Hence, sturdy for long life. An automatic lubrication pump and multiple safety devices are equipped for easy maintenance and safe operation.

Specifications

| Machine Type | S-B18GL | |

|---|---|---|

| Range of Can Dia. | Round 55 - 86mm (For Double Die Setting) | |

| Maximun Can Height | 56mm | |

| Range of Strip Length | 550 - 1050mm | |

| Range of Strip Width | 200 - 300mm | |

| Cans Per Strip | 8 - 16 Cans | |

| Stroke Per Min. | 80 - 100 | |

| Length of Stroke | 200 mm | |

| Maximun Die Height | 420 mm | |

| Maximun Ram Adjustment | 60 mm | |

| Ram Bottom Area | 460 x 360 mm | |

| Bolster Area | 770 x 480 mm | |

| Horse Power Required | Main Motor | 20HP |

| Hydraulic Pump | 2HP | |

| Vacuum Pump | 1/2HP | |

| Scrap Ejector | 1/4HP | |

| Air Compressor | 10HP | |

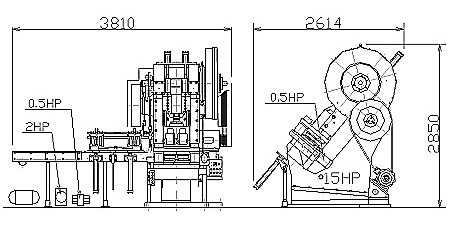

| Floor Space Overall Height | 3805L x 2566W x 2833H mm | |

| Net Weight (approx.) | 11500 kgs | |

Features

- Air clutch is adopted to ensure effective transmission.

- Basic double die design for save of tinplate material.

- Air cylinders are adopted for buffering the movement of big ram, hence precise stamp can be achieved.

- Cylinders are used for top & bottom die cushion to ensure a very smooth drawing of can bodies.

- Centralized lubrication system ensure the smooth running of the machine.

- Double sheet detectors are used to protect the damage of machine & dies.

- Can be connected with automatic strip feeder model S-B18-2 or S-B18-3 to save labor cost and connected with rotary trimmer model S-B61 to trim can flange.

- Equipped with double drawing - reverse - drawing dies.

- 2 pices DRD can also can be formed by two separate drawing procedure.

- Double sheet detector is equipped for safe strip feeding.

Layout Dimension