S-B9AC(ACL,ACLL) Automatic Curling Machine

S-B9AC(ACL,ACLL) Automatic Curling Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

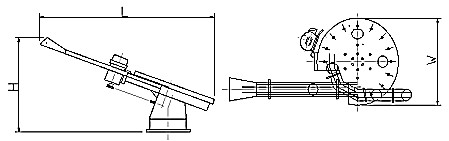

S-B9AC(L,LL) Automatic Curling Machine is designed to inward curl the end fringe on round end. End punched by a press is delivered by a chute or a conveyor into the curling machine. A turning curling disc and a set of fixed curling segment curl the end fringe gradually. A central support ring is to support the end while it is being curled so as to avoid deformation. Simple structure, easy for operation and maintenance.

coming soon

Specifications

| Machine Type | S-B9AC | S-B9ACL | S-B9ACLL |

|---|---|---|---|

| Range of Can Dia. | 200 - 401 D | 401 - 603 D | 603 - 800 D |

| Capacity Per Min. | Up to 250 Ends | Up to 150 Ends | Up to 120 Ends |

| Horse Power Required | 1/4 HP | ||

| Floor Space Overall Height | 1540 x 740 x 800 mm | 1660 x 860 x 800 mm | 1660 x 1075 x 800 mm |

| Net Weight (approx.) | 150 kgs | 180 kgs | 230 kgs |

Features

- Tooling is made from special alloy steel and harden treatment.

- End guide with stainless steel or polish treatment.

- Easy adjustment and quickly for changeover.

- Can connect with conveyor to linning and drying M/C to reduce labor cost.

- Perfect products and buit for long life satisfy the requirement of can making.

- Can be used for aerosol cone/dome curling.

- Nine piece outer segments is equipped for each wheel.

- With non-motorized end guide inlet chute.

- More inward curl on cap can be done by S-B14C

Layout Dimension