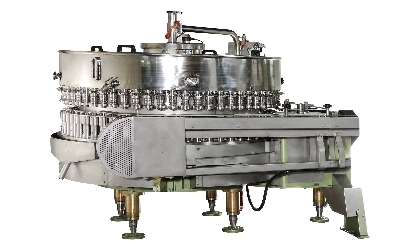

S-C7-60A Automatic Liquid Filler Machine

- Home

- Products

- Food canning machine

- Automatic Filler

- S-C7-60A

S-C7-60A Automatic Liquid Filler Machine

S-C7-60A Automatic Liquid Filler is specially designed for round can liquid filling. Empty cans are carried into lifter plate via a timing screw and a turret. Lifter plate is lifted up by a lower cam to lift can to press the filling valve. Filling valve is to be pressed to open then fill liquid into can by gravity force. Air releases from can through a vent. Filled cans are carried out by a discharge turret and chain to approach a seamer. Liquid level in tank is controlled by sensor bars and a solenoid valve. With 60 sets of filling valve, steady filling volume. Simple structure and multiple safety devices, easy for operation and maintenance.

Specifications

| Machine Type | S-C7-60A |

|---|---|

| Filling Valves | 60 SETS |

| Range of Can Dia. | 202 - 307D |

| Range of Can Height | 68 - 180mm |

| Dia. of Liquid Tank | 2250mm |

| Volume of Liquid Tank | 115 GAL |

| Capacity Per Min. | Up to 700 Cpm |

Features

- Uniform filling volume within 1mm head space.

- Suitable for fruit juice with sac.

- Filling valves and liquid tank are made of SUS 316.

- Easy cleaning and maintenance.

- Quick changeover for different can sizes.

- CIP Unit on your requirement.

- Liquid filled by gravity force.

- All parts contact with can/lid are made of stainless steel or bronze.

Layout Dimension

coming soon