S-D21 Automatic Twist-Off Cap Pre-Curler Machine

S-D21 Automatic Twist-Off Cap Pre-Curler Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

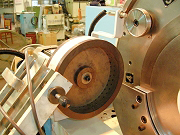

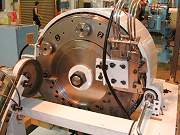

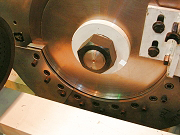

- Close View / Tooling

- Specification / Features

S-D21 Automatic Twist-Off Cap Pre-Curler is designed for the cap fringe inward tiny curl. Cap shells, made by press, are lifted up by an elevator and guided to enter the machine via a chute. Six sets of inner curling rollers enter cap inside and carry caps travel along an arc outer curling mold to slightly curl the cap fringe inward. Curled caps are carried out one by one by a magnetic wheel and guided by a chute to enter knurl forming and lining machine S-D21. Simple structure and multiple safety devices, easy for operation and maintenance.

coming soon

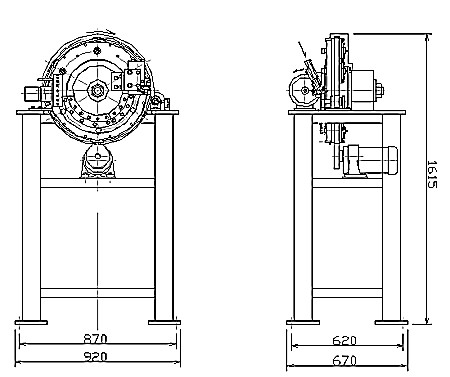

Specifications

| Machine Type | S-D21 |

|---|---|

| Range of Can Dia. | Φ30 - 96mm |

| Capacity Per Min. | Up to 120 cpm |

| Horse Power Required | 3HP x 1 |

| Floor Space Overall Height | 920L x 700W x 1630H mm |

| Net Weight | 600 kgs |

Features

- Smooth gravity cup infeeding mechanism to send cups to forming pilots.

- Simplified construction of tool pack minimises operating and maintenance.

- Perfect products and suitable for middle or large lot size manfacture.

- All tooling wear parts are hardened alloy steel to ensure long and perfect production life.

- Full automatic control available.

Layout Dimension