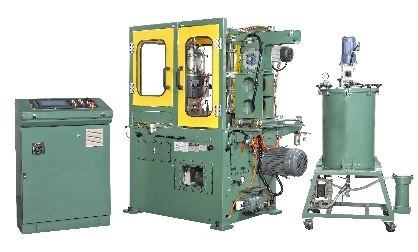

S-B89 Automatic High Speed Rotary Lining Machine

S-B89 Automatic High Speed Rotary Lining Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-B89 Automatic High Speed Rotary Lining Machine is specially designed for high speed production for small round end. Curled end is separated by a pair of spiral separating knives at end magazine; then feeding turret send it into lining station. End is lifted up by a turning chuck and well positioned by a turret. Multiple sets electronic lining guns undertake the lining task to evenly spray compound along the end fringe. Lined ends are transferred by a turret and ejected out via an air blowing guide. Sealing compound is pumped into top central tank from a ground tank via a pump and the control by the level control bars inside the central tank. With recycleable lubricating system and multiple safety devices, easy for maintenance and can size changeover.

Specifications

| Machine Type | S-B89 | ||

|---|---|---|---|

| Model Type | 4H | 6H | 8H |

| Range of Can Dia. | 113 - 401 D | 113 - 301 D | |

| Capacity Per Min. | up to 1000 EPM | up to 1500 EPM | up to 2000 EPM |

| Main Motor | 5HP x 1 | ||

| Lower chuck motor | 3HP x 1 | 5HP x 1 | |

| Floor Space Overall Height | 2640L x 2020W x 1900H mm | ||

| Net Weight | 2650 Kgs | ||

Features

- Twin spiral separating knives, reliable separating and reduce scratch.

- Floating separating knives housing can float up if any end jam during separating to stop machine.

- Electronic lining guns to guarantee perfect compound spray and distribution.

- Five detecting bars inside top central tank to control compound level.

- Lower chuck speed is adjustable to optimize compound spray and distribution.

Layout Dimension