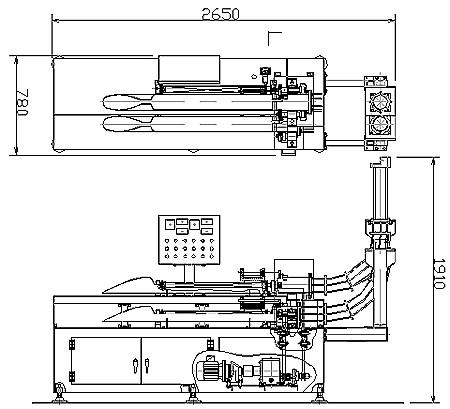

Specifications

| Machine Type |

S-B10A-6 |

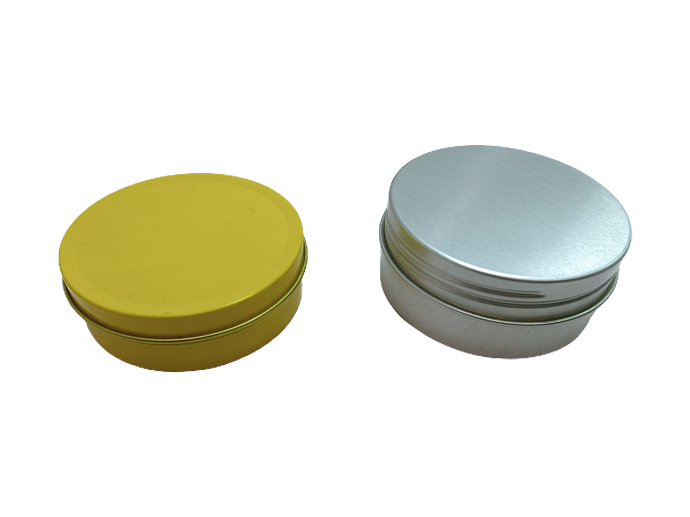

| Range of Can Dia. |

115 - 404D |

| Capacity Per Min. | Food End: Up to 1200 ends/min. Aerosol Cone or Dome:Up to 360 ends/min. |

| Horse Power Required | 1/2HP x 2 |

| Compressed Air Required | 6kg/Cm2 * 20L/min |

| Floor Space Overall Height | 2650L x 780W x 1910H (mm) |

| Net Weight | 700 kgs |

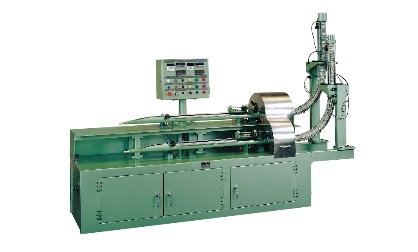

Features

- Mounting with two sets stacking and controller can link to two liners.

- Precise ends counting, quick for resetting and adjusting.

- Multi-safety design for machine and personnel safety.

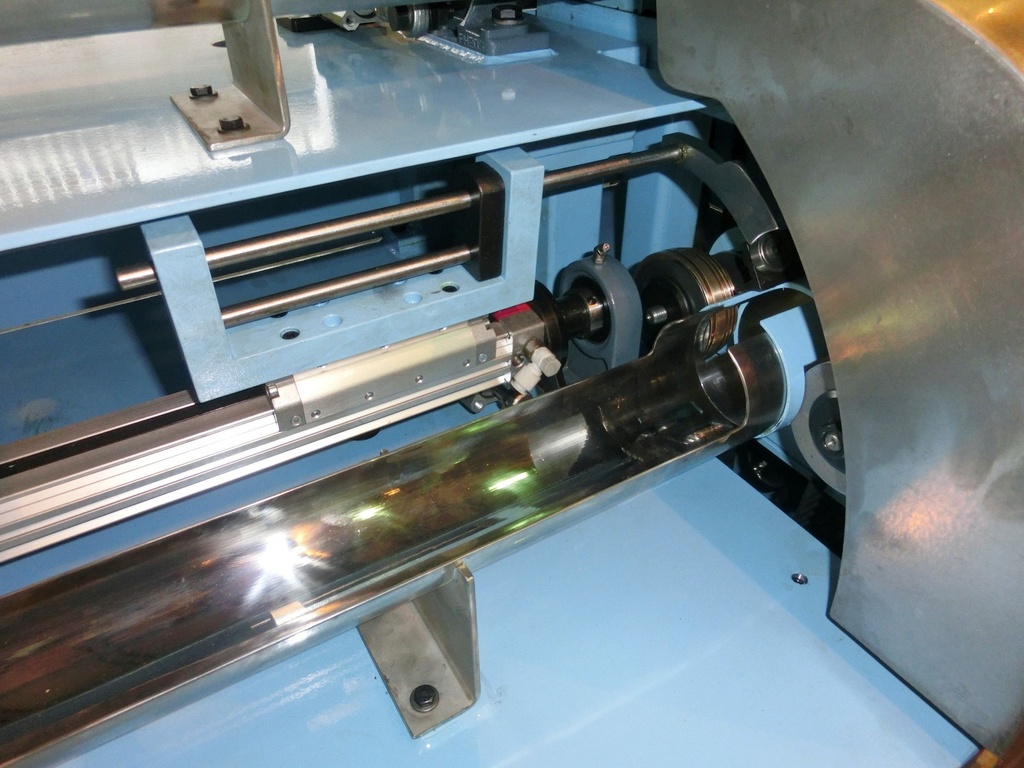

- Suitable for steel and aluminum ends counting and stacking.

- With PLC control system for ends auto stacking and counting operation.

- Equipped with inverter for variable speed control.

- Equipped with two collecting channels.

Layout Dimension