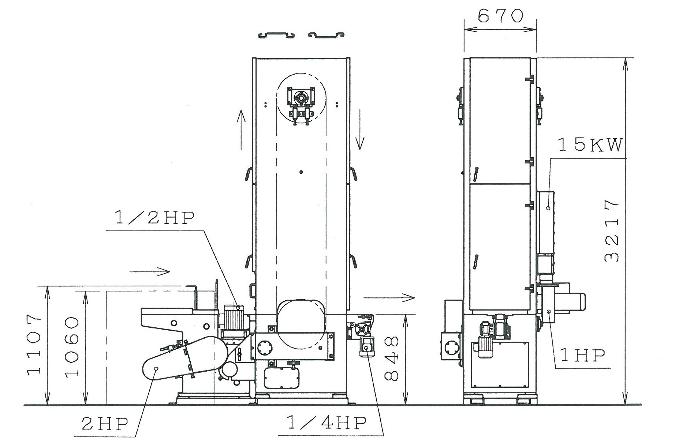

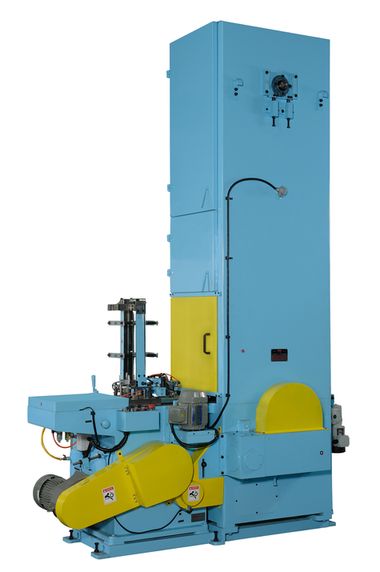

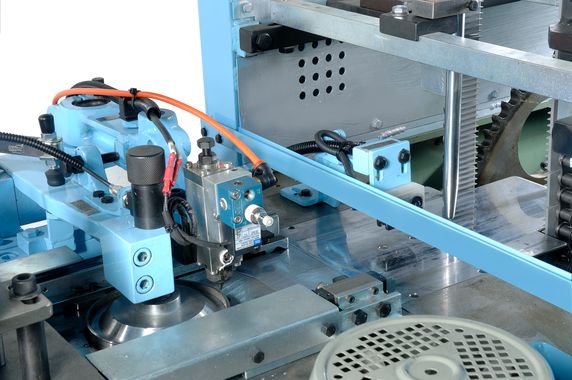

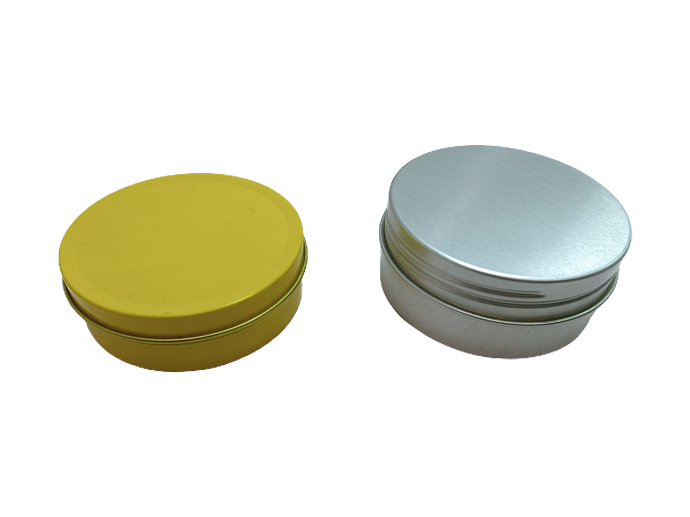

S-B10CL Automatic Lining- Drying Machine is specially designed for round end. Curled end is separated by a pair of swing separating knives at end magazine, then feeding bars send it to lining station. End is lifted up by a turning chuck. A mechanical gun (or electronic gun) undertake the lining task to evenly spray compound along the end fringe. Lined ends are sent into drying oven directly by end feeding bars. Oven walls are thermal insulating layer designed, inside the drying oven, heating air is created and circulated by an electric heater and a blower. Ends are carried up through two pocket chains, turned over at oven top and carried down. Dried ends are ejected by a conveyor from the bottom of the oven. With circulating lubricating system and multiple safety devices, easy for maintenance and can size changeover.