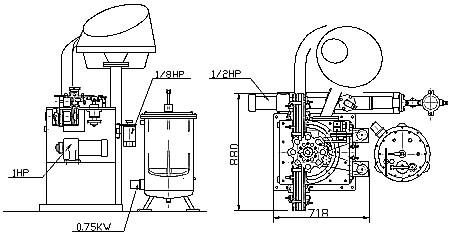

S-B10TC Automatic Twist-Off Cap Lining Machine is designed for the sealing compound spraying on twist-off cap. Formed cap is carried into by a conveyor , then is sent to an index turret to lining station. A set of electronic lining gun undertake compound spraying task. Then, lined cap is turned by a disc to evenly spray compound on the cap by centrifugal force. Compound can be distributed along cap fringe circumference or cap whole round surface. Simple structure and multiple safety devices, easy for operation and maintenance.