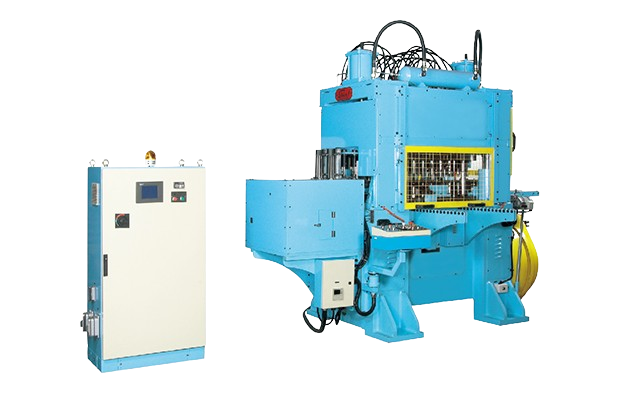

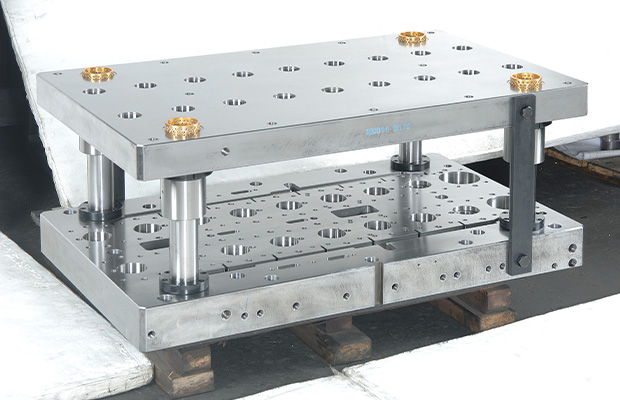

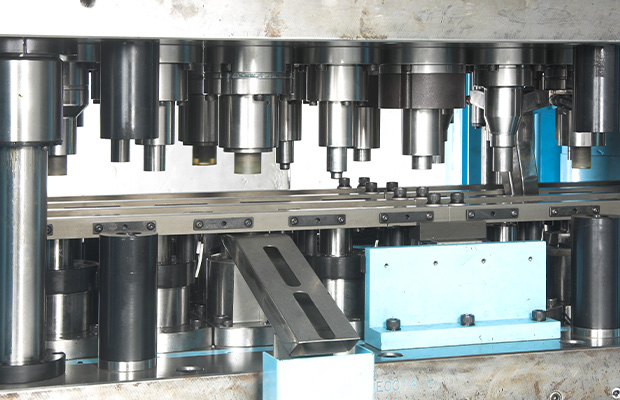

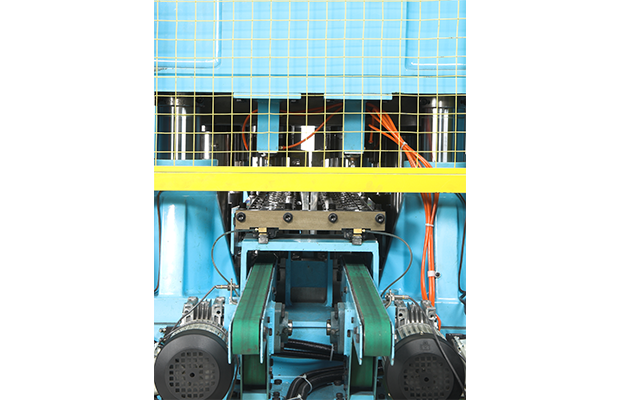

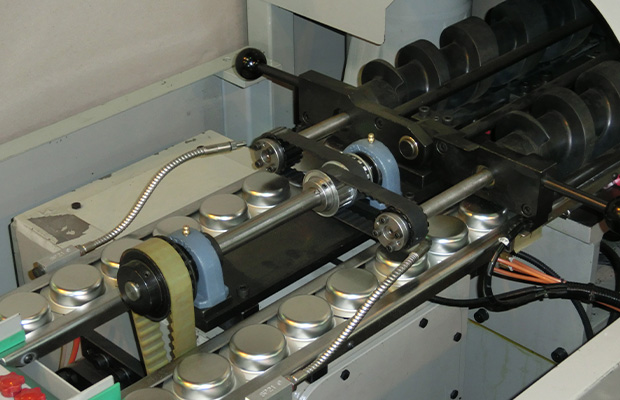

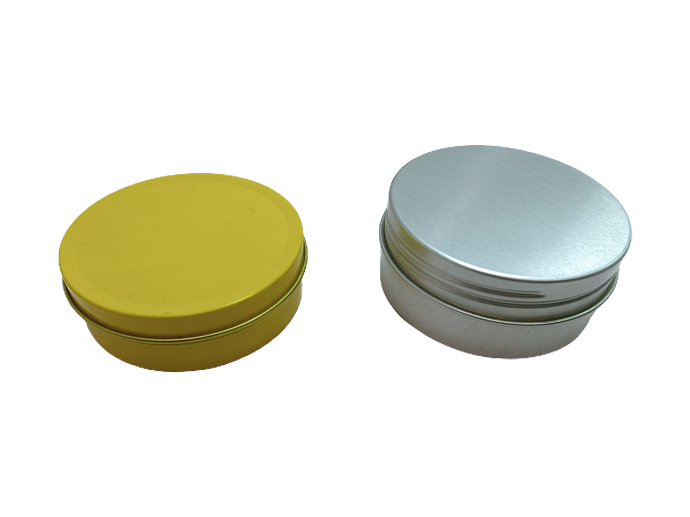

S-B110B Automatic Transfer Press specially designed to produce aerosol top end, spray lid and threaded oil end. It can be built for single lane or double lanes depending on end size. Max.number of the tooling can be 9 stations for each lane. Capacity can be 100~150 strokes per minute. Therefore, max.capacity can reach 300 pcs per minute. Material is fed into entrance screw type or magnet type separating unit via a conveyor. reciprocating end feeding system equipped with several clippers send end into tooling, An end pusher located at the upper tooling hold the end to let the clippers release the end. Then, upper tooling punch down to form the end. When upper tooling goes up to a certain position, clippers send the end to next station timely. When end is formed at the final station, end is pressed down by a pneumatic pusher to a discharge conveyor.