Specifications

| Machine Type |

S-B17V |

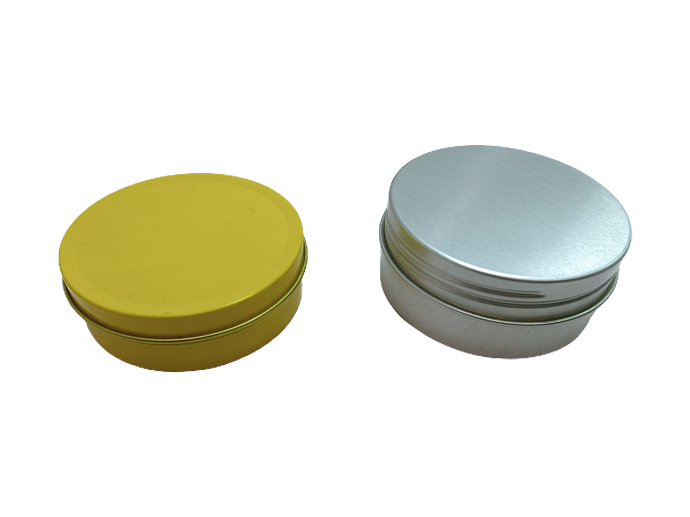

| Range of Can Dia. |

202 - 401D |

| Range of Can Height | 4H、8H: 90 - 210 mmH 12H: 90 - 180 mmH |

| Capacity Per Min. | 4H: Up to 300 Cans 8H: Up to 600 Cans 12H : Up to 900 Cans |

| Horse Power Required |

4H、8H: 3HP 12H: 7.5HP |

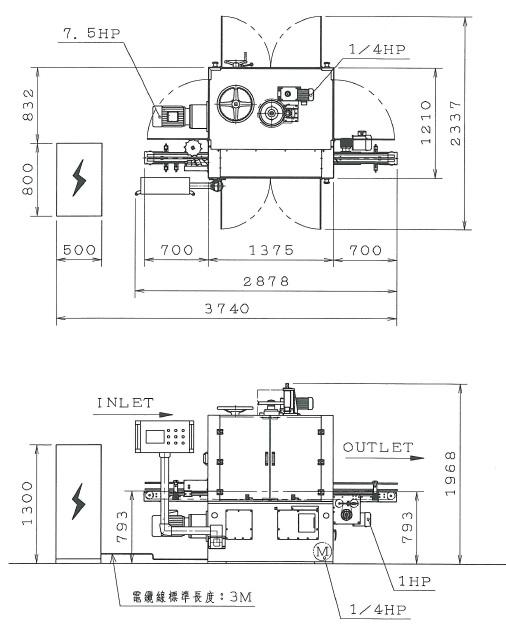

| Floor Space Overall Height | 2725L x 1330W x 1820H (mm) |

| Net Weight | 4H: 4,500 kgs 8H: 4,800 kgs 12H: 5,500 kgs |

Features

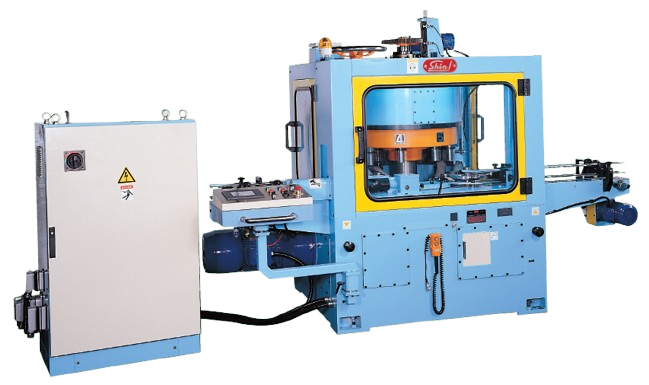

- Vertical design easy to connect with auto double seamer.

- Recycleable central control lubricating system.

- Use human-machine interface (touchable monitor) control system and inverter for setup and variable speed control.

- Use inverter for variable speed control.

- Full automatic control system for canmaking line requirement.

- Multi-safety design for machine and personnel safety.

- Beads on can body are formed due to pressing between turning beading roller and a fixed arc beading rail.

Layout Dimension