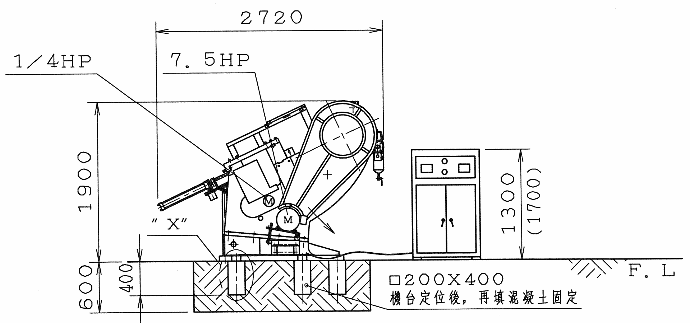

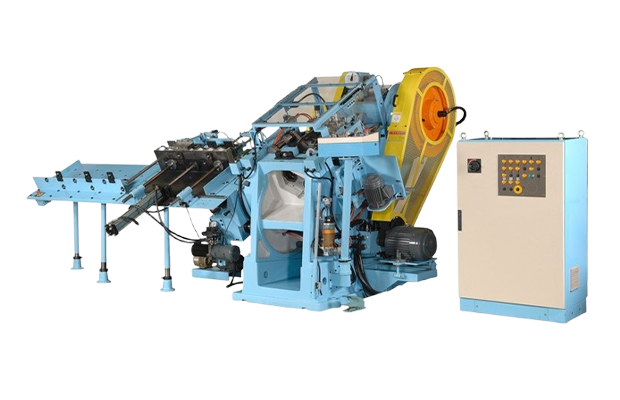

S-B18D Automatic Double Dies Press is built for small can end stamping. Piled strips are lifted by a set of hydraulic cylinders then suck pads send strip one by one to strip feeding station. (also can link with Automatic Strip Feeder S-B18-2M). Reciprocating feeding bar at feeding station push strip into punch tooling. Formed can end is ejected out via. end kickers (or air blowing) to rear while strip scrap is ejected out by a pressing roller to side. Equipped with dual dies or four dies (for end smaller than 202D). Punch tooling is made of alloy steel; hence, sturdy for long life.

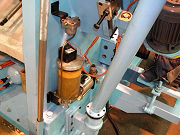

An automatic lubrication pump and multiple safety devices are equipped for easy maintenance and safe operation.