Specifications

| Machine Type |

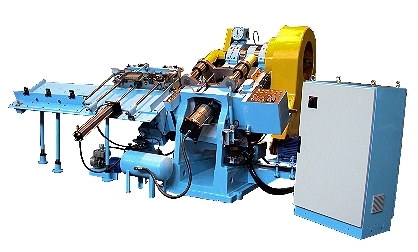

S-B18GL |

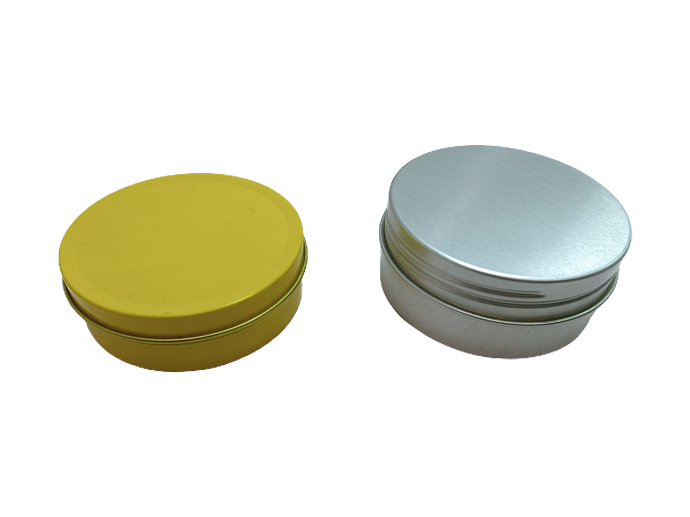

| Tinplate Size | L: 500-1025mm W: 200-300mm (oval end: 200-335mm) |

| Range of Can Dia. |

211-307D (Double dies) 401D (Single die) |

| Maximum Can Height | Up to 56mm |

| Stroke Per Min. | Up to 80-100 spm |

| Horse Power Required | 20 HP |

| Hydraulic Pump | 2 HP |

| Scrap Discharger | 1/4 HP |

| Vacuum Pump | 1/2 HP |

| Length of Stroke | 200mm |

| Maximum Die Height | 420mm |

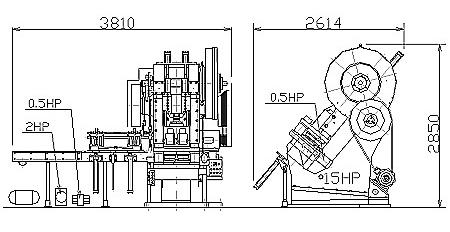

| Floor Space Overall Height | 3805L x 2566W x 2833H (mm) |

| Net Weight | 11,500 kgs |

Features

- Air clutch is adopted to ensure effective transmission.

- Basic double die design for save of tinplate material.

- Air cylinders are adopted for buffering the movement of big ram, hence precise stamp can be achieved.

- Cylinders are used for top & bottom die cushion to ensure a very smooth drawing of can bodies.

- Centralized lubrication system ensure the smooth running of the machine.

- Double sheet detectors are used to protect the damage of machine & dies.

- Can be connected with automatic strip feeder model S-B18-2 to save labor cost and connected with rotary trimmer model S-B61 to trim can flange.

- Equipped with double drawing - reverse - drawing dies.

- 2 pices DRD can also can be formed by two separate drawing procedure.

Layout Dimension