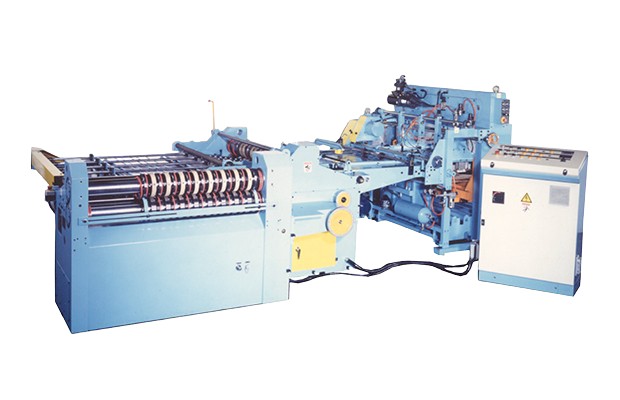

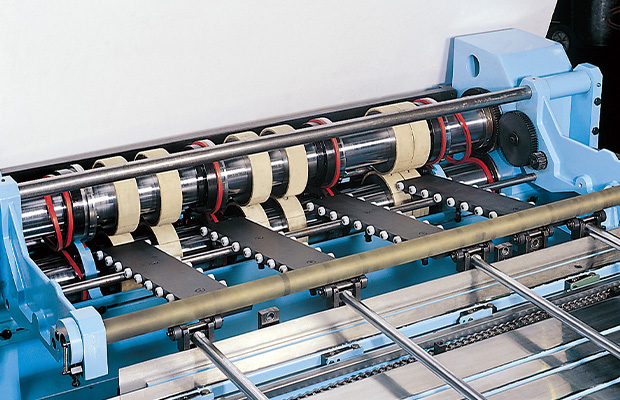

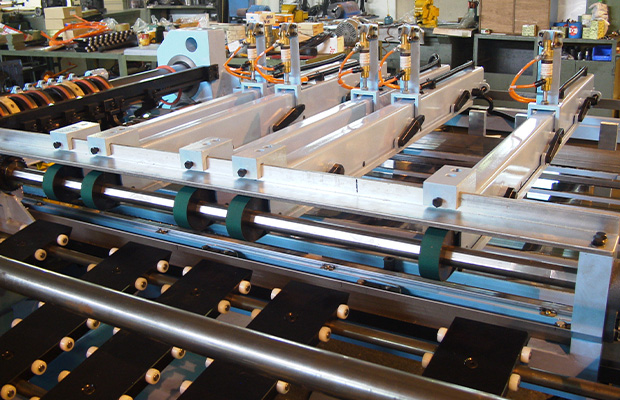

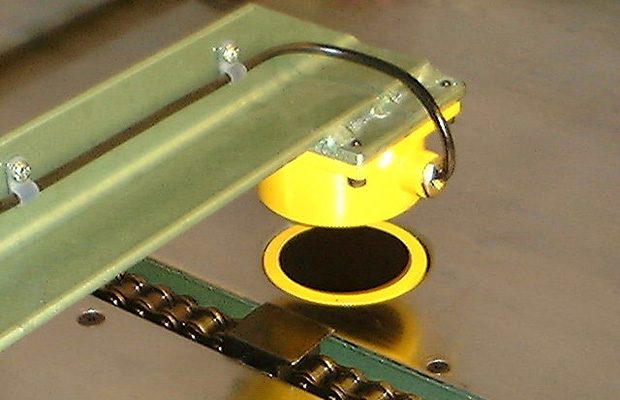

S-B34(M) Automatic Gang Slitter is designed for can body blank cutting and is recommended to link with Automatic Sheet Feeder S-B23B. Sheet is sent to first feeding table, guided by a pair of flexible roller guiding bars and is fed into round cutters via two fingers. Long strips are support by several swing bars (or magnetic belts) then fall down to second feeding table by gravity. Strips are guided by a pair of flexible straight bars and are fed into round cutters via two fingers. With cutter shaft diameter 110mm, reliable mechanical clamping system and tungsten carbide cutter blades, make squareness precise can reach +/- 0.04mm. Number of cutter set can be easily added or removed through main frame side hole. With simple design and multiple safety devices, easy for maintenance and can size changeover.