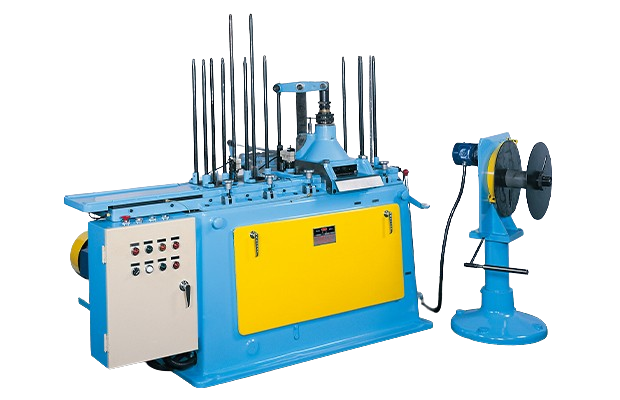

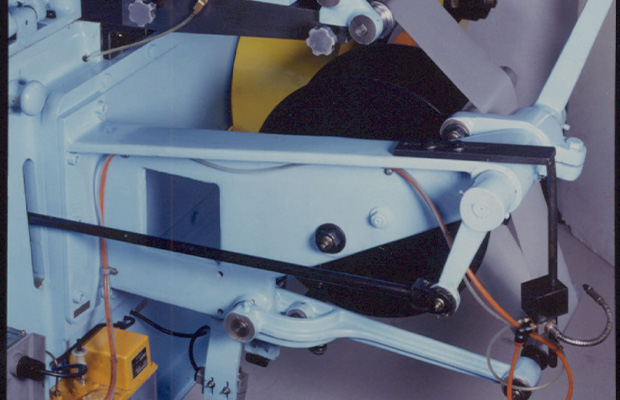

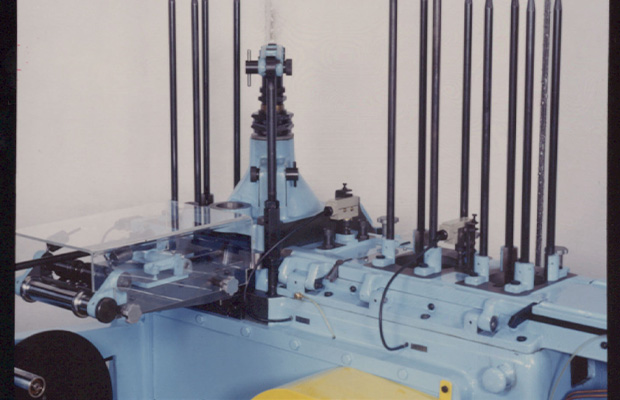

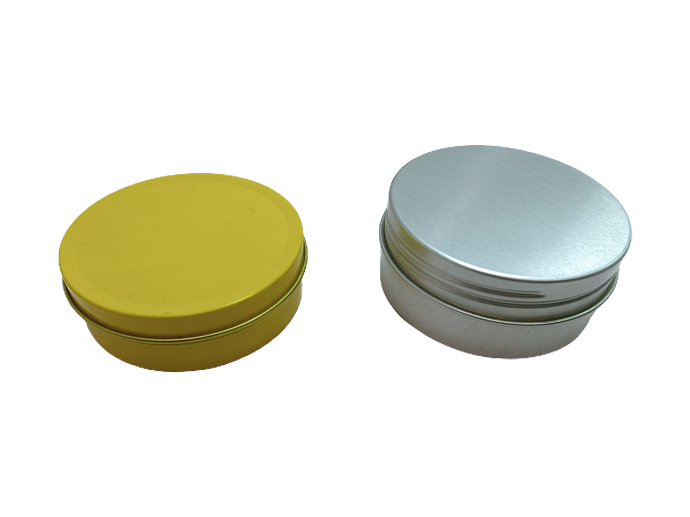

S-B40L(LL) Automatic Assembly Unit is specially designed for milk powder can top end making. Ring ends and central lids are piled up at two end magazines. Ring end and lid is combined together at first stage and recombined with aluminium membrane at second stage. A complete roll of aluminium membrane is positioned at feeding unit and is gradually fed into assembly station by a pusher. Aluminium membrane is cut round by a pair of cutters and is pushed properly into curl area of ring end. Composite ends are lifted up and ejected by a lower plate. Simple design and multiple safety devices, easy for maintenance and can size changeover.