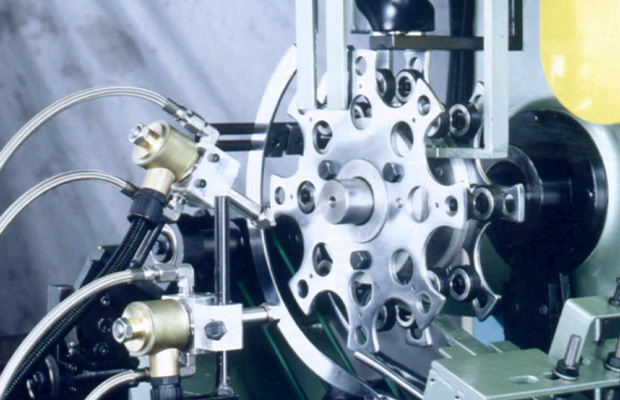

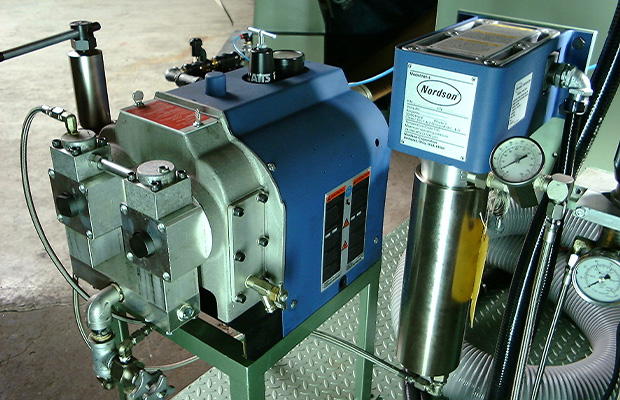

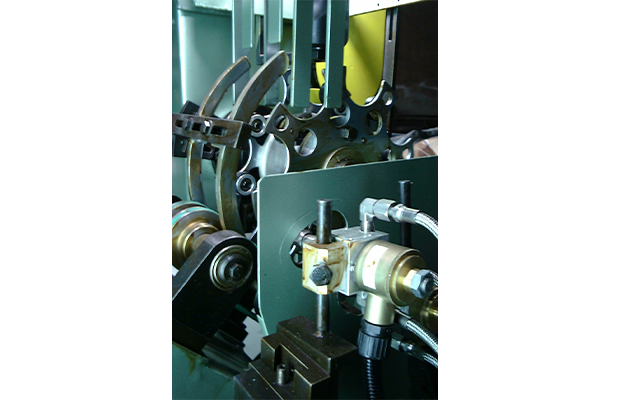

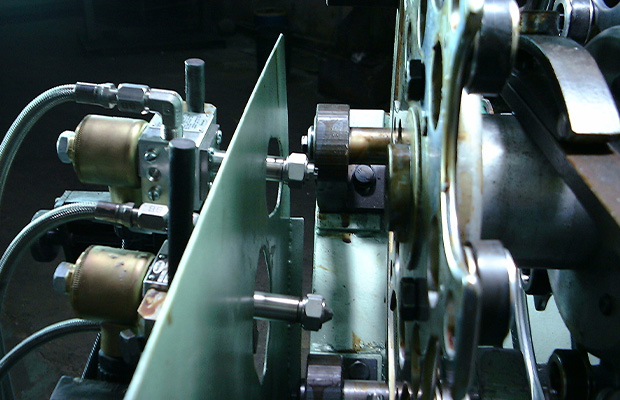

S-B53D Automatic Inside Spray Machine is built for three-piece tin can production. One side sealed can body is fed into from two top can chutes, carried into two spraying stations by two-timing screw and turrets. Two sets of NORDSON spraying guns undertake the spraying job on each station; the first gun is for can wall spraying while the second gun is for can bottom. The spraying angle can be adjusted easily. While being sprayed, the can is supported by an indexing turret and turned by tangent friction force from two belts. Sprayed cans eject from the bottom exit naturally. Equipped with two spraying stations. With NORDSON spraying system and anti-explosion motor, steady and safe. Multiple safety devices are equipped for easy maintenance and safe operation.