Specifications

| Machine Type |

S-B54 | S-B54H | |||

| Model Type | 4H | 8H | 12H | 4H | 8H |

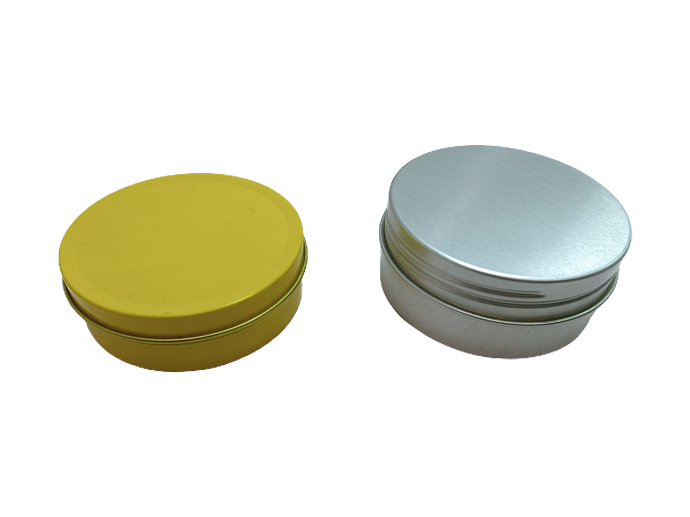

| Range of Can Dia. | 200 - 401D | 200-401D | 200 - 301D | 200-401D | 200-401D |

| Range of Can Height | 70 - 180 mmH (35 - 140 mmH for short can) | 70 - 180 mmH (35 - 140 mmH for short can) | 70 - 180 mmH (35 - 140 mmH for short can) | 80-340mmH | 80-340mmH |

| Capacity Per Min. | UP TO 400 CPM depend on can size | UP TO 800 CPM depend on can size | UP TO 1200 CPM depend on can size | 150 - 275/180-340 CPM depend on can size | 450-720 CPM depend on can size |

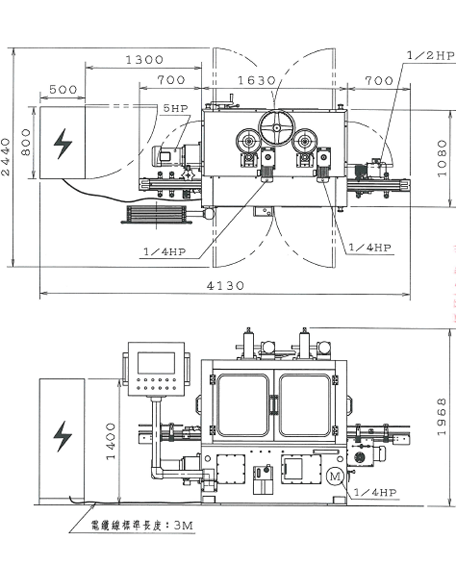

| Horse Power Required | 5HP | 5 HP | 7.5HP | 5HP | 5HP |

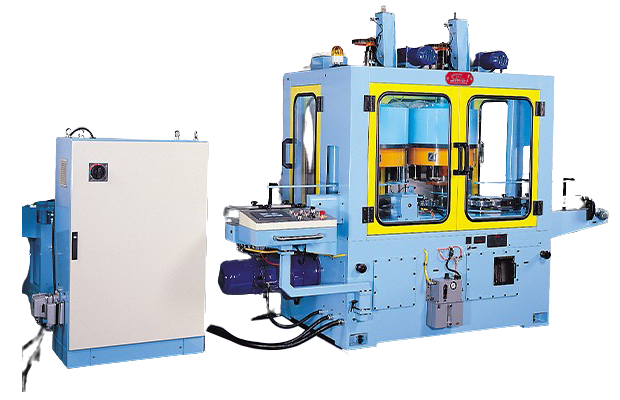

| Floor Space Overall Height | 2910 mmL x 1180 mmW x 1810 mmH | 2910 mmL x 1180 mmW x 1810 mmH | 2910 mmL x 1180 mmW x 1810 mmH | 3830 mmL x 2440 mmW x 2250 mmH | 3830 mmL x 2440 mmW x 2250 mmH |

| Net Weight | 3800 kgs | 4200 kgs | 5000 kgs | 3800 kgs | 4200 kgs |

Features

- Vertical design easy to connect with auto double seamer.

- Recycleable central control lubricating system.

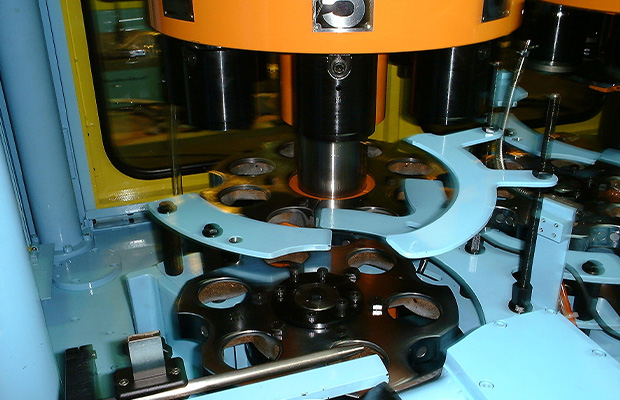

- Can guide and turret with hard chromium plating of nylon material.

- Use human-machine interface (touchable monitor) control system and inverter for setup and variable speed control.

- Full automatic control system for canmaking line requirement.

- Multi-safety design for machine and personnel safety.

- S-B54H Special for Aerosol cans.

- Material for necking inner core is high speed steel, Carbide material is available on request.

- Material for necking outer guide die is tungsten carbide.

- Flanging tooling can be swing type (standard offer) or spin type (customer request).

- Swing flanging works by two symmetric swing discs while spin flanging works by several gear driven rollers.

- Flanging system can be spin or swing type.

Layout Dimension

VIDEO