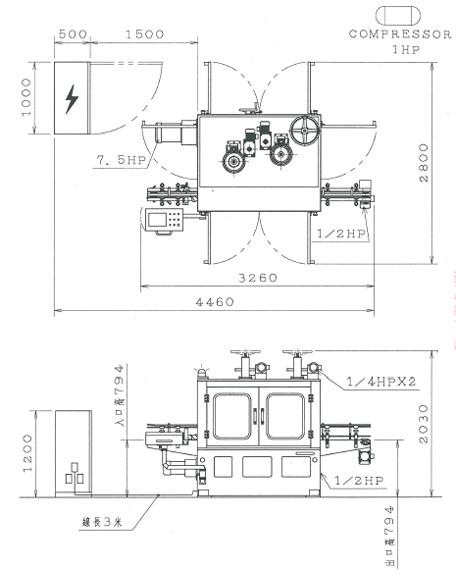

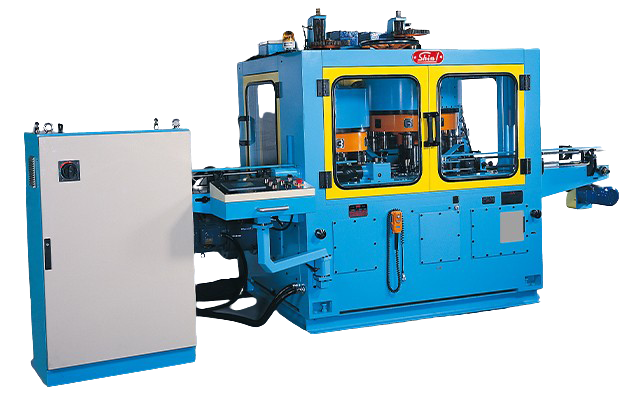

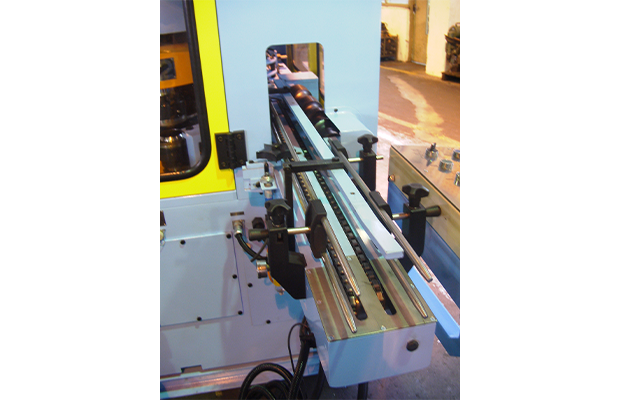

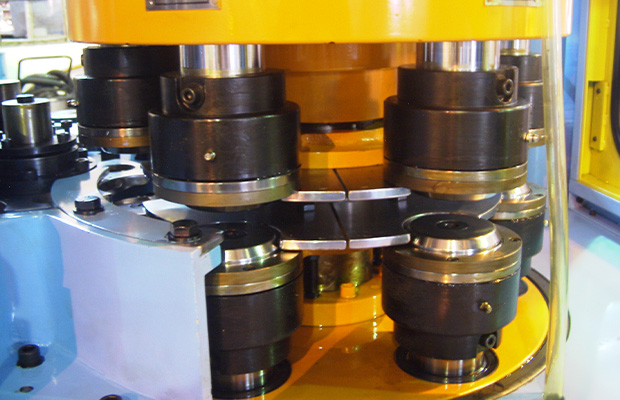

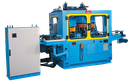

S-B55 Automatic Vertical Flanger with Beader with vertical design is easily linked and work together with automatic double seamer. Can cylinder is carried by a timing screw and a turret to let swing flanging die (or spin flanging die) form flange. Then , flanged can body is transferred by a turret to let beading roller enter can inside. Bead clusters are created due to pressing between beading roller and a fixed arc beading rail. Swing flanging works by two symmetric swing discs to squeeze can fringe while spin flanging works by several turning rollers to squeeze can fringe. With recycleable centralized lubricating system and multiple safety devices , easy for maintenance and can size changeover.