Specifications

| Machine Type |

S-B70 |

| Model Type | 9H |

| Range of Can Dia. | 200 - 307D |

| Range of Can Height | 70 - 190 mm |

| Capacity Per Min. | Up to 500 Cpns |

| Horse Power Required | 20HP x 1 |

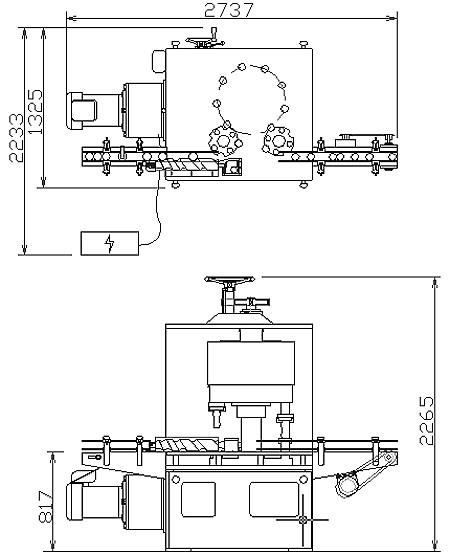

| Floor Space Overall Height | 2890L x 2171W x 2205H mm |

| Net Weight | 5400 kgs |

Features

- Vertical design easy to connect with auto double seamer.

- Recycleable center control lubricating system.

- Use human-machine interface (touchable monitor) control system and inverter for setup and variable speed control.

- Can guide and Turrets with hard chromium plating or Nylon material.

- Full Automatic Control system for canmaking line requirement.

- Multi-safety design for machine and personnel safety.

- Capacity depends on can size and expansion ratio.

- Can shape according to customer's request.

- Recommended Can body tinplate : T2.5 - T3

- Can shape is formed by several expanding strips expanded by two (or three) carbide pushers driven by two cams.

Layout Dimension