Specifications

| Machine Type |

S-B9ACL | S-B9ACLL |

| Range of Can Dia. |

200 - 603D | 603- 800D |

| Capacity Per Min. | Up to 150 Ends | Up to 120 Ends |

| Horse Power Required | 1/4 HP | 1/4 HP |

| Floor Space Overall Height | 1660 L x 860 W x 800 H (mm) | 1660 L x 1075 W x 800 H (mm) |

| Net Weight | 180 kgs | 280 kgs |

Features

- Tooling is made from special alloy steel and harden treatment.

- End guide with stainless steel or polish treatment.

- Easy adjustment and quickly for changeover.

- Can connect with conveyor to linning and drying M/C to reduce labor cost.

- Perfect products and buit for long life satisfy the requirement of can making.

- Can be used for aerosol cone/dome curling.

- Nine piece outer segments is equipped for each wheel.

- With non-motorized end guide inlet chute.

- More inward curl on cap can be done by S-B14C.

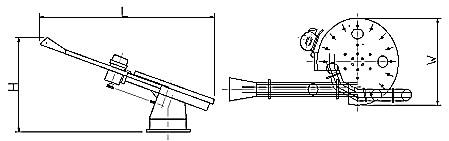

Layout Dimension