Specifications

| Machine Type | S-B9C | S-B9CL |

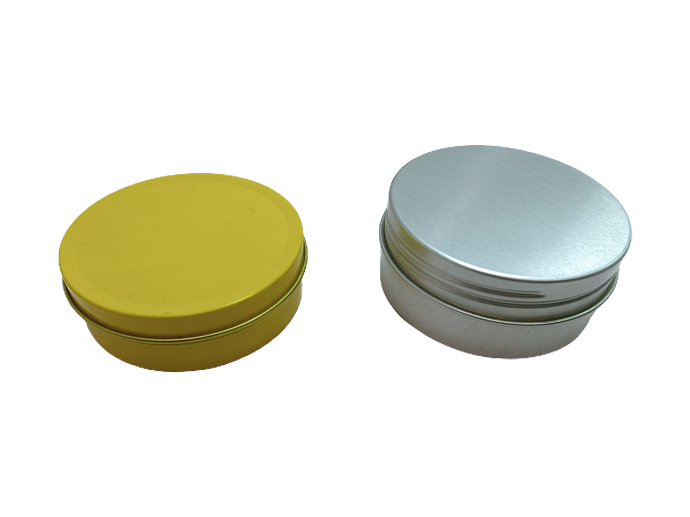

| Range of Can Dia. | 50mm-102mm ~ C3B; 87mmx116mm | 60mm-240mm |

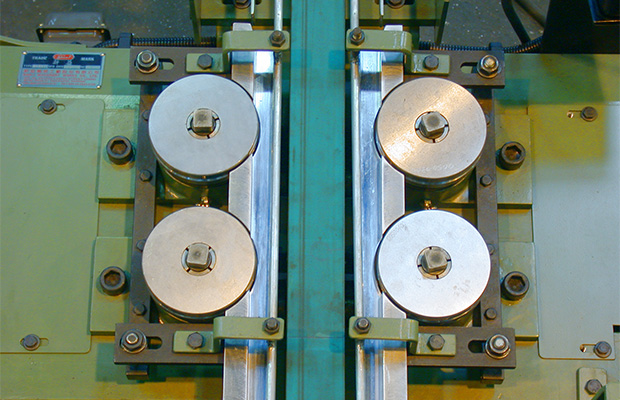

| Curling Wheel | Two ways | Two ways |

| Capacity Per Min. | Up to 400 cans | Up to 120 Ends |

| Horse Power Required | 1/4 HP | 1/4 HP |

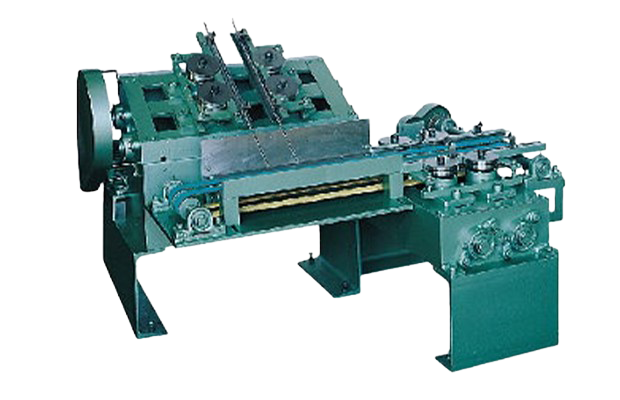

| Floor Space Overall Height | 890L x 615W x 840H (mm) | 1200L x 1050W x 600H (mm) |

| Net Weight | 100 kgs | 160 kgs |

Features

- Tooling is made from special alloy steel and harden treatment.

- End guide with stainless steel or polish treatment.

- Easy adjustment and quickly for changeover.

- Can connect with conveyor to linning and drying M/C to reduce labor cost.

- Perfect products and buit for long life satisfy the requirement of can making.

- Irregular ends also can be curled by press toolings.

Layout Dimension