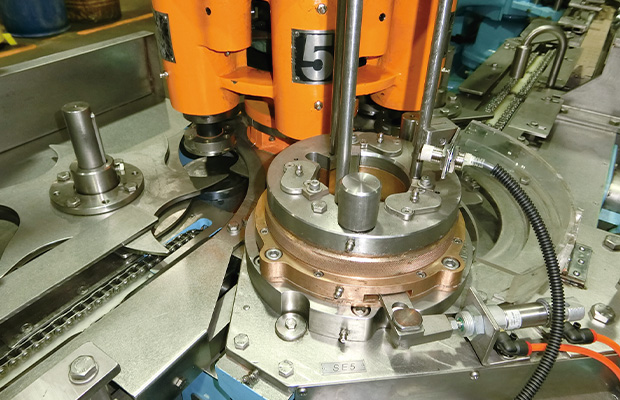

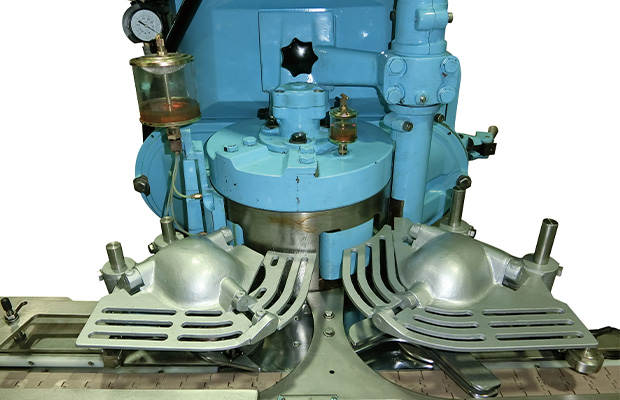

S-C4A + S-C9 Automatic 3H Vacuum Seamer is specially designed for round can closing under vacuum . Filled can is fed forward through a timing screw and a chain to enter a clinching station, round chuck and an fixed arc clinching make end and can clipped together. Small gap between end and can for air suction in vacuum chamber later. Clinched can is transferred forward into a vacuum chamber with three seaming heads. Lifter plate lift can up in vacuum chamber. Four seaming rollers undertake seaming operation. Seam quality meet international standard. Simple structure and multiple safety devices, easy for operation and maintenance.