Specifications

| Machine Type | S-C91 |

|

| Range of Can Diameter | ∅53-99mm | |

| Range of Can Height | 30-150mmH | |

| Capacity per Min | UP TO 40-100CPM | |

| Main Motor | 5 HP | |

| Vacuum pump | 7.5HP | |

| Floor Space Overall Height | 2560L × 1420W × 2310H mm | |

| Net Weight (approx) | 4600 kgs | |

Features

- Rigid machine structure, suitable for various can seaming operations.

- After the can body and lid are aligned at the inlet, they pass through a clinching plate to ensure they are securely joined.

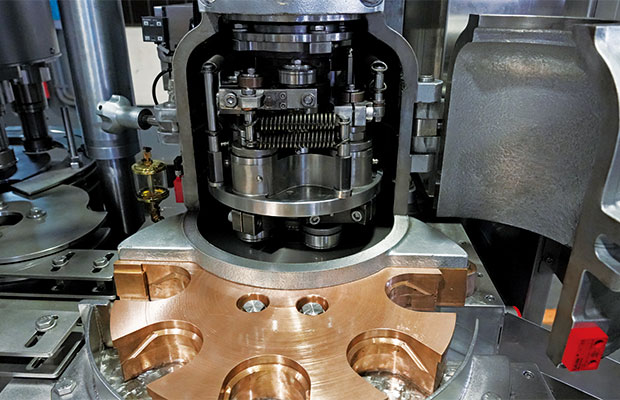

- The advancement and retraction of the seaming rollers are fully controlled by a seaming cam, ensuring precise movement and easy adjustment.

- The seaming head structure is compact and sturdy, making it easy to operate and maintain.

- Equipped with an electronic sensor for the "no can - no lid" mechanism, which is precise and effective. If lid-feeding abnormalities occur, the machine will automatically stop and trigger a warning light.

- Uses a frequency inverter for speed regulation. The start, stop, acceleration, and deceleration controls are extremely smooth, effectively reducing inertial impact and extending the machine's lifespan.

- Features multiple safety controls, such as main clutch disengagement, "no lid" detection, motor overload, and emergency stop for can jams.

- The lid-feeding system can be integrated with the customer's automatic delivery system, and optional lid-clamping devices can be added.

VIDEO