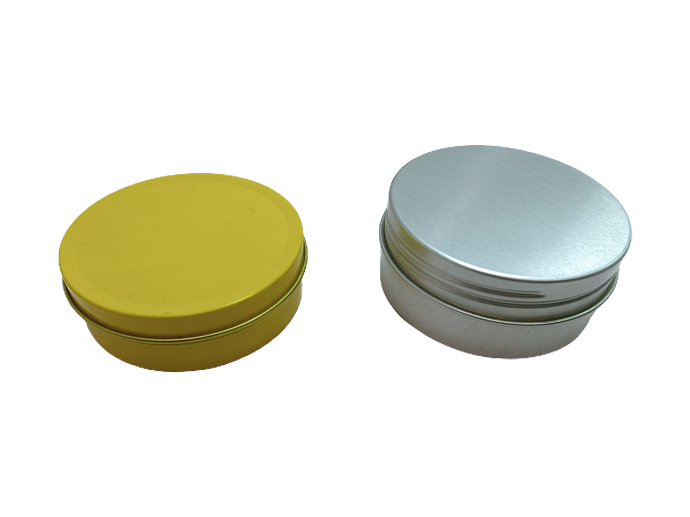

S-D36A is a combination of curling, lining and drying units. It was well designed for irregular tinplate or aluminum ends. The ends should be pre-curled by pre-curling machine, then to S-D36A curler and liner. The ends to be separated by twin end separating disc, and the dogs push end onto each lower chuck to let it engaged each other for ends curling, lining and drying operation.

After lining, ends feed to oven for compound drying. Oven use electrical heating wires for water base compound drying. Two vertical transferring roll chains with comb shape pockets to transfer the ends to travel up and down, the comb shape pocket made of plastic material can stand high temperature up to 120° C, and avoid scratches on the ends.