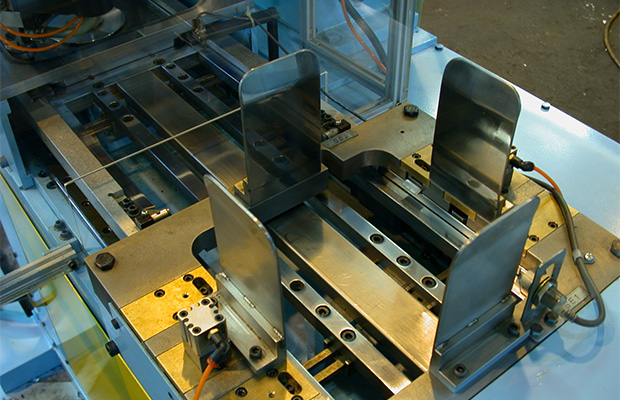

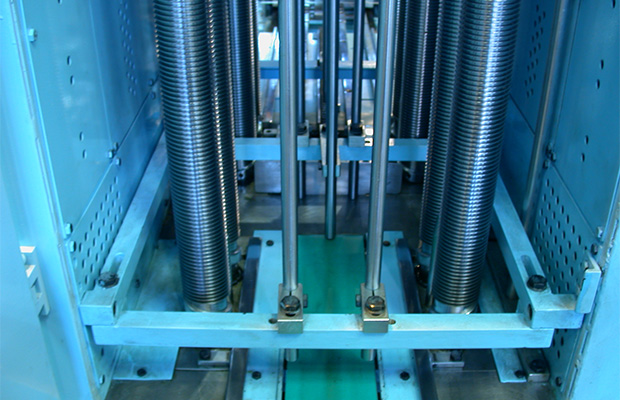

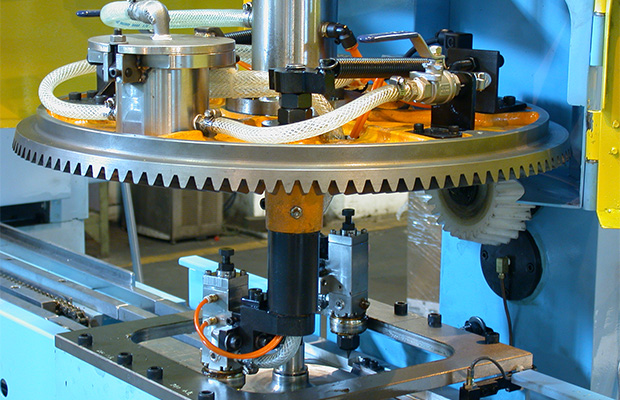

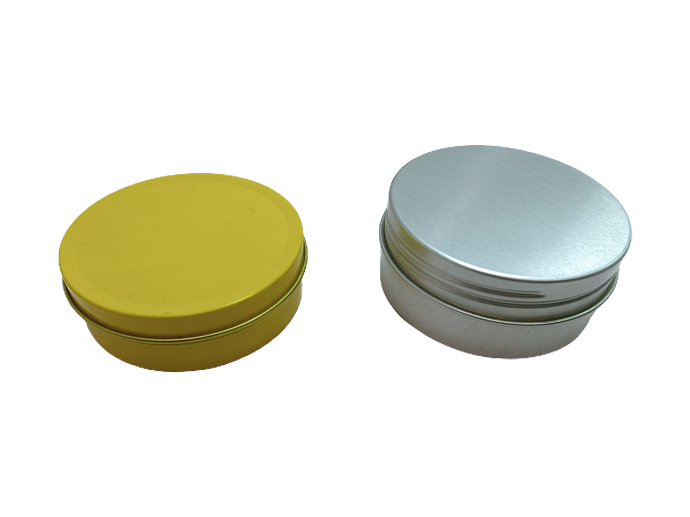

S-D25 Automatic Five Gallon Square End Lining and Drying Machine is designed for five gallon tin bottom end. Curled end is separated by a pair of separating knives on the end magazine; then, end is smoothly fed forward via two end pushing bars guided by linear bearings. Two sets of electronic lining guns undertake compound lining. Guns turn along end fringe according to a cam contour. Lining time is controlled by a sensor and a timer. Lined ends are guided by several transfer screws up and down inside the drying oven. Heating air is created and recycled through two sets of electric heater and blower. Simple structure and multiple safety devices, easy for operation and maintenance.